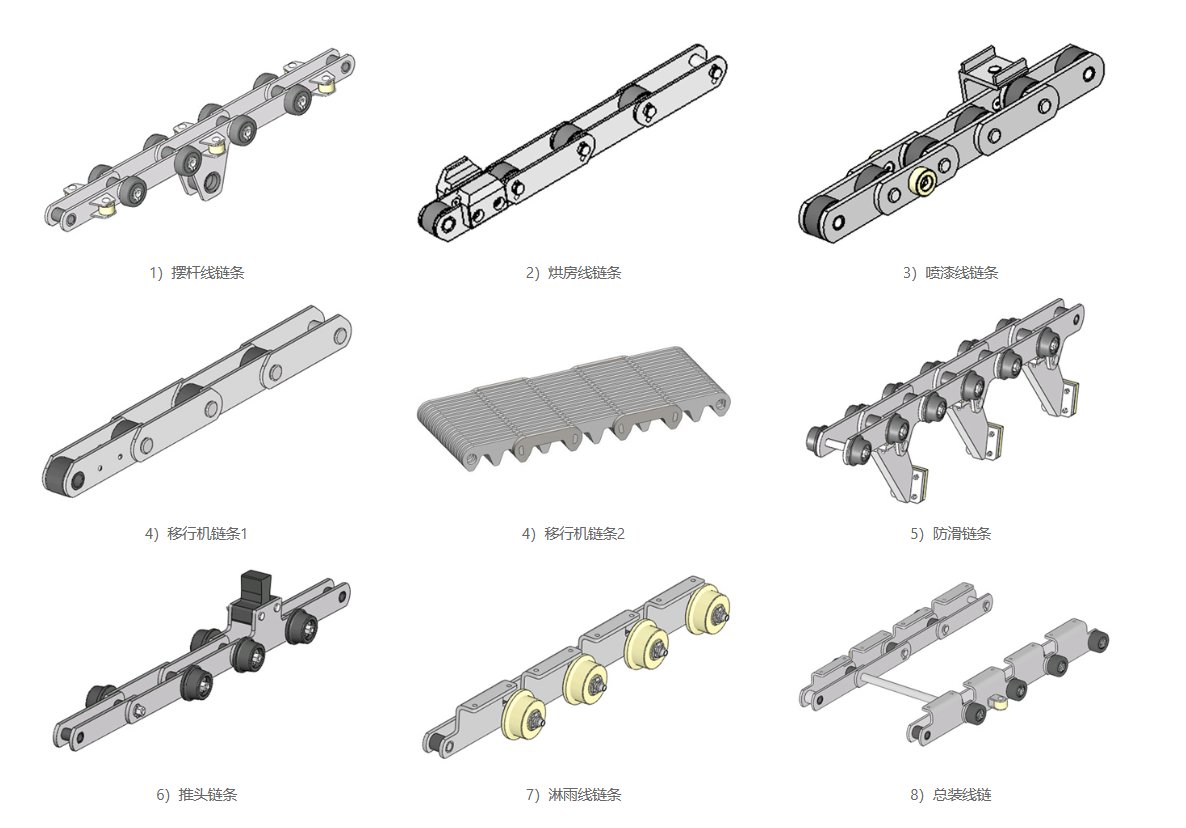

The car production line chain mainly refers to the various conveying chains used in the automotive manufacturing logistics transportation system. According to customer needs, it provides chains with a variety of styles and different functions according to different production areas.

Various types of transport chains have the following characteristics:

1. Placing rod line chain: adopt the design of the external formula of the roller wheel and the oil injection hole structure, to achieve smooth operation of the chain and extend the service life;

2. During the drying line chain: use special design to meet the high temperature use of 250 C to ensure the reliable operation of the production line

3. Spray lacquer line chain: choose high -quality materials and precise manufacturing to meet the use of in a specific environment

4. Migration machine chain: Special design high -strength roller chain and large -section distance bias chain to ensure efficient operation of different production lines

5. Anti -slip chain: It has anti -slip structure design, which can effectively prevent the body from falling and ensure the safe operation of the production line

6. Push head chain: By optimizing design, products are widely used in spray paint, welded, dry houses and other processes to meet the car cars with carrier body on the track. 7. Sending high -quality stainless steel materials and precision manufacturing, manufacturing, precision manufacturing, and precision manufacturing, and precision manufacturing, and precision manufacturing, it is manufactured. Meet the environment that runs in water for a long time

8. Connecting line chain: According to the characteristics of the production line, the main products include various types of dental conveying chains, long -section distance conveying chains, and the tensile strength reaches 450kn.